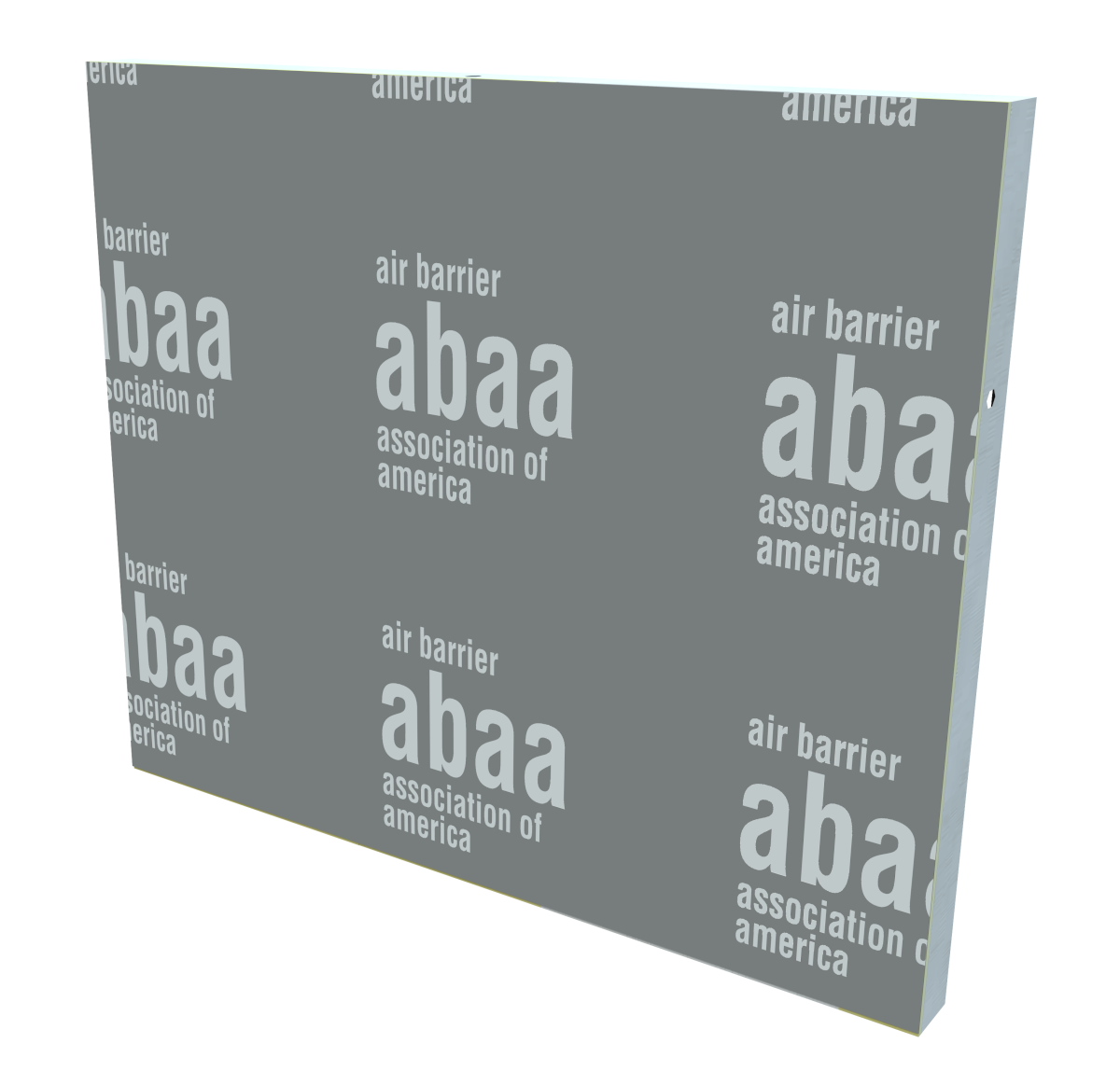

The ABAA conducts comprehensive assessments on a variety of materials to validate them as suitable air barriers. These evaluations address key inquiries, including the material’s durability, continuity, ability to withstand building movements, contractions, expansions, and resistance to wind and diverse weather conditions.

This scrutiny extends to factors such as accommodating building movement, water resistance, crack bridging capability, and conventional code, taking into consideration the physical and architectural attributes essential for an effective air barrier.

ASTM E2178

Standard: Only measures air permeance (leakage) of an air barrier material.

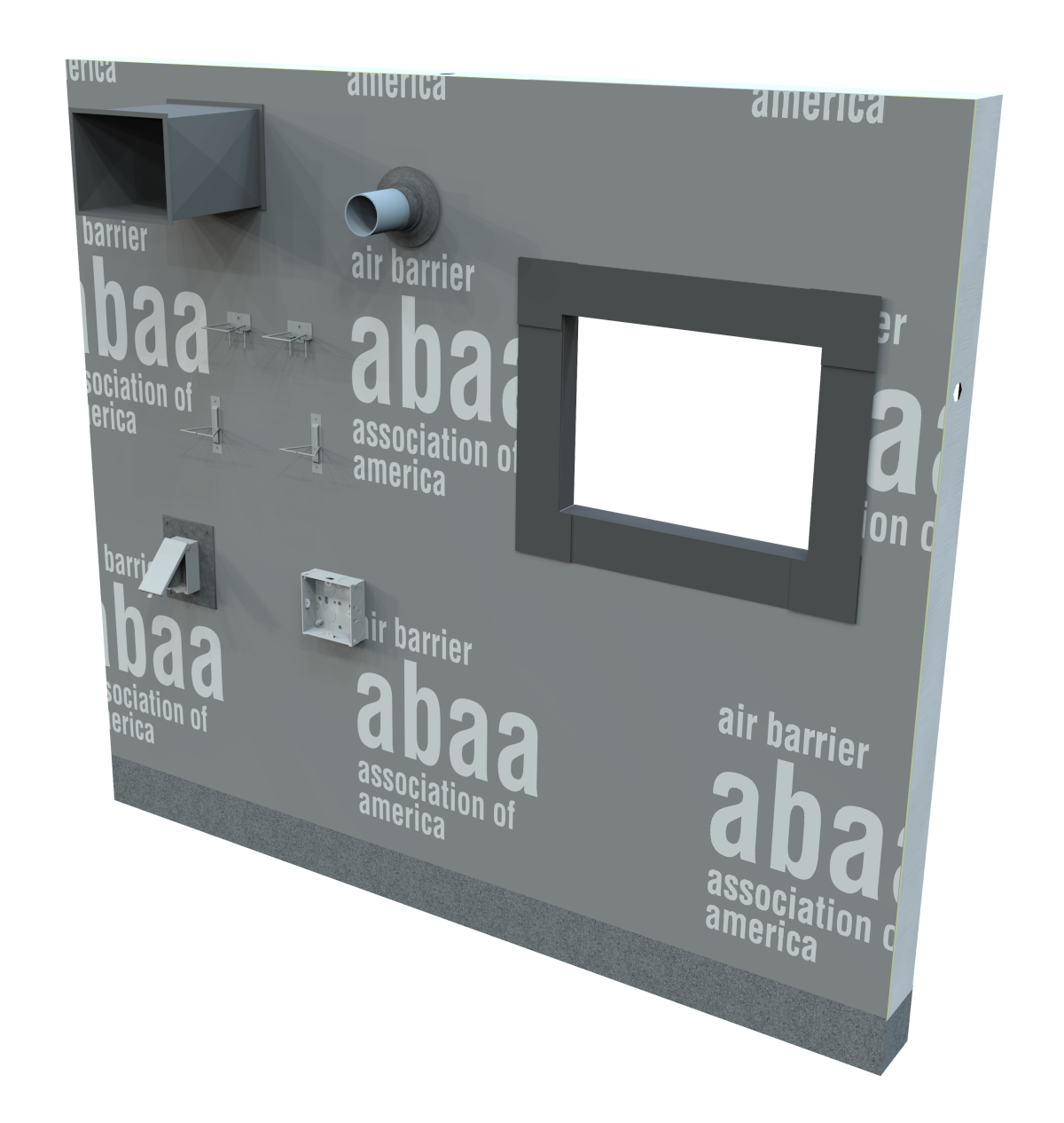

ASTM E2357

Standard: Measures air permeance (leakage) of air barrier materials/accessories when combined into a wall assembly with pipe penetrations, brick ties, electrical boxes, foundation transitions, lap seams and flashings. See below for more detailed information.

Bottom Line: ASTM E2357 is a more REALISTIC test method emulating installed materials on a building.

What is ASTM E2357?

Published in 2005, ASTM E2357 Standard Test Method for Determining Air Leakage of Air Barrier Assemblies measures the performance of an assembled system rather than the amount of air leakage through a single component. The installed assembly is tested under a multitude of negative and positive air pressures including extreme wind gust load conditions.

The ASTM E2357 test method measures and compares the air leakage through an ‘opaque’ non-penetrated wall assembly against the air leakage through a wall assembly with pipe penetrations, brick ties, electrical boxes, foundation transitions and lap seams and flashings. The walls are subjected to extreme positive and negative wind load conditions and the measured air leakage recorded. If the measured air leakage rate passing through the wall with penetrations is greater than 10% of the opaque wall, the assembly fails.

How does ASTM E2357 differ from previous testing standards?

It’s important to note that codes regulate air leakage rates or limits; test methods verify the performance characteristics. The more common requirement for acceptable air leakage rate is set at 0.004 cfm/ft2 when subjected to 1.57 psf of air pressure. One such test method used is ASTM E2178 Standard Test Method for Air Permeance of Building Materials. In addition to flexibility, tensile strength and a few other durability tests, it measures the air permeance of individual materials, but only to 1.57 psf of air pressure. With the introduction of ASTM E2357, it is realized most building projects experience significantly higher wind loads, both negative and positive than 1.57psf. ASTM E2357 verifies the Air Barrier System Approach will stand up to the extreme weather conditions a building enclosure may experience during its lifetime.

ASTM E96 Desiccant

Procedure A – Dry Cup (desiccant method)

The test specimen is sealed to the open mouth of a test dish containing a desiccant and the assembly placed in a controlled atmosphere. Periodic weighing determine the rate of water vapor movement through the specimen from the controlled atmosphere (50%RH) into the desiccant (0%RH). Desiccant pellets at the bottom of the cup and weighed in the chamber.

ASTM E96 Water

Procedure B – Wet Cup (water method)

The test specimen is sealed to the open mouth of a test dish containing water and the assembly placed in a controlled atmosphere. Periodic weighing determine the rate of water vapor movement through the specimen from the water (100%RH) to the controlled atmosphere (50%RH).